Explosion Testing for dust, gases & vapours

© January 2026

Thermal Decomposition Screen

Thermal Decomposition Screening Test

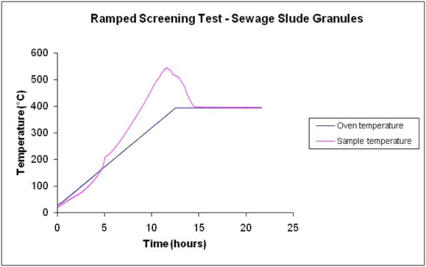

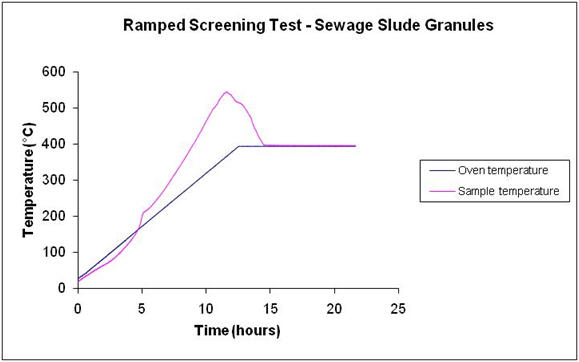

Self-heating materials are relatively common and have caused numerous fires in processing and storage facilities throughout the world. It is there important to identify at an early stage any new material to be handled that may be susceptible to self-heating. Heat generated by oxidation, the most frequent source of self-heating, produces heat at a rate which is a function of temperature. Heat will be generated within the pile and lost from the surface. Since the rate of reaction increases rapidly with temperature and since the heat generated in a pile of material depends on the pile’s volume and the net rate of heat loss from the pile’s surface depends on the surface-to-volume ratio, generated heat may not be in balance with the heat lost. The thermal decomposition screening test is designed to identify materials prone to self-heating. The test is carried out in a high temperature oven fitted with a forced air circulation fan and digital programmable temperature control. The controller has a dedicated thermocouple to provide control feedback and an independent high temperature cut-off thermocouple. The oven temperature is programmed to increase from ambient at 0.5 o C per minute up to a target of 400 o C with a holding period of 60 minutes at 105 o C to allow any moisture to be driven off. The material under test is held in an open topped 100mm cube wire mesh basket with a central thermocouple connected to data logging. The criterion for a positive test is the central temperature of the sample exceeding that of the oven by 60°C or more. Samples are usually tested “as received” since the physical form of a material can affect its self-heating properties. The graph below shows a typical temperature / time trace for a self-heating substance.

- Classification test

- Explosion indices test

- 1m3 explosion test

- Minimum ignition energy

- Minimum ignition temperature

- Layer ignition temperature

- Limiting oxygen concentration

- Lower explosible limit

- Isothermal basket test

- Powder volume resistivity

- Train fire

- Thermal screen

- Air Over Layer

- UN Classification testing

Explosion Testing

© January 2026

Thermal

Decomposition Screen

Thermal Decomposition

Screening Test

Self-heating materials are relatively common and have caused numerous fires in processing and storage facilities throughout the world. It is there important to identify at an early stage any new material to be handled that may be susceptible to self-heating. Heat generated by oxidation, the most frequent source of self-heating, produces heat at a rate which is a function of temperature. Heat will be generated within the pile and lost from the surface. Since the rate of reaction increases rapidly with temperature and since the heat generated in a pile of material depends on the pile’s volume and the net rate of heat loss from the pile’s surface depends on the surface-to-volume ratio, generated heat may not be in balance with the heat lost. The thermal decomposition screening test is designed to identify materials prone to self- heating. The test is carried out in a high temperature oven fitted with a forced air circulation fan and digital programmable temperature control. The controller has a dedicated thermocouple to provide control feedback and an independent high temperature cut-off thermocouple. The oven temperature is programmed to increase from ambient at 0.5 o C per minute up to a target of 400 o C with a holding period of 60 minutes at 105 o C to allow any moisture to be driven off. The material under test is held in an open topped 100mm cube wire mesh basket with a central thermocouple connected to data logging. The criterion for a positive test is the central temperature of the sample exceeding that of the oven by 60°C or more. Samples are usually tested “as received” since the physical form of a material can affect its self- heating properties. The graph below shows a typical temperature / time trace for a self-heating substance.